Crude oil and natural gas are two of the most important energy resources globally, powering industries, transportation, and homes alike. While both are fossil fuels derived from the earth, they differ significantly in terms of their composition, physical properties, extraction processes, and environmental impacts.

Crude oil is a liquid hydrocarbon that is primarily used for transportation fuels like gasoline and diesel, as well as for industrial applications. In contrast, natural gas is a gaseous fuel that has gained popularity as a cleaner alternative for electricity generation and heating.

In midstream operations, the infrastructure and logistics for oil and gas may overlap, but the unique properties of each fuel require different approaches for storage, transport, and handling. As energy markets evolve and the push for cleaner, more efficient energy grows; understanding the contrasts between crude oil and natural gas in the midstream sector becomes crucial for assessing their roles in the future of energy distribution.

Let us take a closer look at the differences between crude oil vs natural gas processing.

#Natural gas processing vs oil refining

Natural gas processing typically involves:

Separation: The first step involves separating the raw natural gas from other extracted substances, like water, sand, and oil.

Removal of Contaminants: Impurities like hydrogen sulfide (H₂S), carbon dioxide (CO₂), and water are removed through a series of processes such as amine gas treating or molecular sieves.

Separation of Natural Gas Liquids (NGLs): NGLs are extracted from the gas through cooling, absorption, or fractionation to produce products like propane, butane, and ethane.

Drying: The final processed gas (often referred to as "dry natural gas") is mostly methane and is ready for transmission through pipelines.

Meanwhile, crude oil refining is a more multi-step process that involves:

Distillation: The crude oil is first heated and distilled to separate it into different fractions based on boiling points (e.g., gases, gasoline, kerosene, diesel, etc.).

Cracking: Larger, heavier hydrocarbons (such as those in gas oil) are broken down into lighter, more valuable products like gasoline and diesel through processes like catalytic cracking or hydrocracking.

Reforming: Some fractions of crude oil, such as naphtha, are treated to improve their quality or change their chemical structure (e.g., for making higher-octane gasoline).

Blending: Different fractions are blended together to meet specifications for final products like gasoline or diesel.

.jpeg)

#Natural Gas vs. Oil: Comparing the Challenges of Processing and Refining

While natural gas processing can be technically challenging, it involves less steps than oil refining. The complexity lies in removing impurities and extracting the NGLs in a way that ensures both environmental and operational efficiency.

On the other hand, crude oil itself contains a broad spectrum of hydrocarbon chains therefore, oil refining is a high-energy process that requires sophisticated technology and precise control over chemical reactions, which often produces large amounts of waste and emissions.

As far as the storage requirement of these energy resources is concerned, the different ways are mentioned below.

#Crude Oil vs. Natural Gas: Understanding Storage Requirements

Crude oil is a liquid at room temperature, which makes it easier to store in tanks and transport through pipelines.

It is stored in large above-ground storage tanks (tank farms) or underground storage tanks (salt caverns or depleted oil reservoirs in some cases).

This is often bulk storage, which allows for the accumulation of significant quantities of oil, particularly at key transit hubs or pipeline junctions.

Natural gas is a gas at room temperature, so it needs to be compressed or liquefied to make it feasible for transport and storage.

It is often stored in underground reservoirs or in pressurized tanks for local distribution. It may also be stored as LNG (Liquefied Natural Gas) for international transport or in CNG (Compressed Natural Gas) form for certain applications.

This storage is more about pressure and temperature control rather than sheer volume. Underground storage is generally used for long-term or seasonal supply, while LNG storage is used for large-scale transport.

.jpeg)

#Midstream Storage: Balancing Safety, Seasons, and Commodity-Specific Needs

In the midstream sector, safety considerations, environmental impacts, and seasonal demand also play significant roles in determining how each commodity is stored and managed. The infrastructure for oil storage is more focused on volume capacity, while gas storage is more concerned with pressure and temperature control to ensure safe and reliable delivery.

Storage facilities for crude oil are often designed to accommodate seasonal fluctuations in demand or supply, though long-term storage is less common for crude oil since it is usually sent to refineries for processing.

Natural gas storage is more likely to be driven by seasonal demand. Gas is stored during low-demand seasons (e.g., summer) and withdrawn during peak-demand periods (e.g., winter).

Now moving on towards the transportation of crude oil and natural gas, these include the following methods.

#Transporting Energy: Infrastructure Essentials for Crude Oil and Natural Gas

Crude oil is primarily transported by pipelines, rail, and tankers. The midstream infrastructure for crude oil includes extensive pipeline networks, marine terminals, and rail networks.

Pipeline Transport: Large-diameter pipelines are commonly used to transport crude oil across vast distances, often involving numerous pumping stations to maintain flow.

Rail & Tankers: In regions without pipeline access, crude oil is transported via rail cars or tanker ships, especially for international trade.

Natural gas is mostly transported via pipelines, but it requires more specialized infrastructure due to its gaseous nature.

Pipeline Transport: Gas pipelines are smaller in diameter compared to oil pipelines and operate under high pressure. They require compression stations at regular intervals to maintain flow, as natural gas can lose pressure over long distances.

LNG & CNG: To transport gas over long distances where pipelines are not feasible, natural gas is either liquefied into LNG (by cooling it to -162°C) or compressed into CNG for road transport. LNG is typically transported in specialized LNG tankers, while CNG is transported in large containers via trucks.

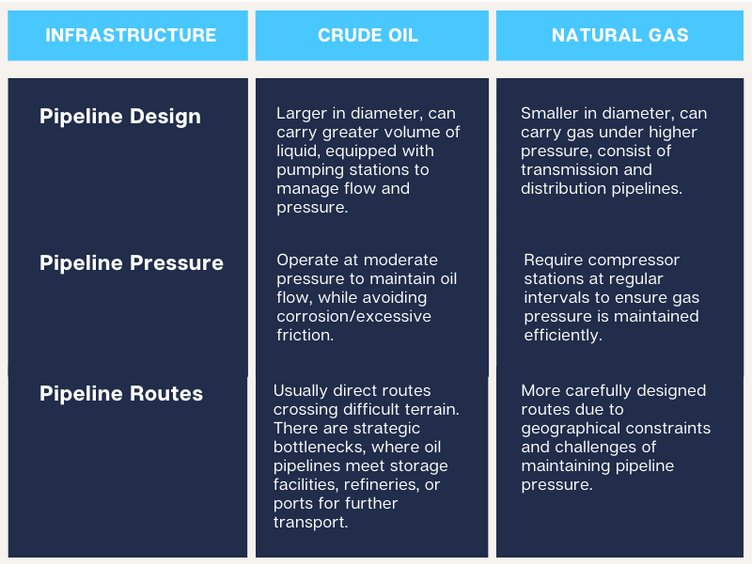

#Differences in pipeline infrastructure (crude oil vs natural gas)

Here are some of the key differences in the transportation of crude oil and natural gas based on their pipeline infrastructure.

Table of contents

- Natural gas processing vs oil refining

- Natural Gas vs. Oil: Comparing the Challenges of Processing and Refining

- Crude Oil vs. Natural Gas: Understanding Storage Requirements

- Midstream Storage: Balancing Safety, Seasons, and Commodity-Specific Needs

- Transporting Energy: Infrastructure Essentials for Crude Oil and Natural Gas

- Differences in pipeline infrastructure (crude oil vs natural gas)